Dye Intermediates

Product Details:

- Shelf Life 24 Months

- Solubility Soluble in specific organic solvents

- Moisture (%) <1.0%

- Shape Powder / Granular

- Molecular Formula Varies depending on compound

- Rubbing Resistance High

- Water Resistant Yes

- Click to view more

Dye Intermediates Price And Quantity

- 10000 INR/Kilograms

- 500 Kilograms

Dye Intermediates Product Specifications

- Dye Manufacturing

- Powder or Granules

- Odorless or mild chemical odor

- Industrial

- Good light and chemical resistance

- Clear to slightly hazy

- Industrial Grade

- Neutral or as specified

- Varies depending on the specific intermediate

- Odorless / Tasteless

- Varies as per required intermediate

- Yes

- Dyestuff Intermediate

- High

- Varies depending on compound

- Varies as per required intermediate

- Solid

- 99%

- Dye Intermediate Compound

- Soluble in specific organic solvents

- 24 Months

- Powder / Granular

- <1.0%

Dye Intermediates Trade Information

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Delivery Point (DP), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- 1 Kilograms Per Week

- 1 Months

- Yes

- Free samples are available

- as per requirements

- Australia, Central America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, North America

- ISO : 9001 : 2018 Govt. Export House Certified .

Product Description

Dye Intermediates

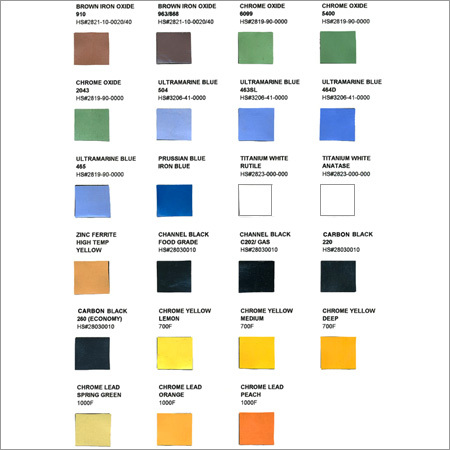

The Dye Intermediates that we provide to our customers is widely used in the textile, plastic, paints, printing inks industry for the manufacturing of a number of different dyes. Obtained using advanced techniques, these colors pose no threat to the skin or health of the user. We pack out products in high quality packaging, in order to protect them from a number of external factors. We supply this Dye Intermediates in various different multi tints and shades according to the needs of our customers.

| 1 AMINO 2 NAPHTHOL 4 SULFONIC ACID |

| 1 DIAZO 2 NAPHTHOL 4 SULFONIC ACID |

| 1 NAPTHOL 3,6 DISULFONIC ACID ( VIOLET ACID ) |

| 1 NAPTHOL 5 SULFONIC ACID ( L ACID ) |

| 1 PHENYL 3 METHYL 5 PYRAZOLONE ( PMP ) |

| 1,3 DIAMINO ISOINDOLENE |

| 1,3 SULFO PHENYL 3 METHYL 5 PYRAZOLONE |

| 1,4 DIAMINO ANTHRAQUINONE |

| 1,4 SULFO PHENYL 3 CARBOXY 5 PYRAZOLONE ( SPCP ) |

| 1,4 SULFO PHENYL 3 METHYL 5 PYRAZOLONE (SPMP) |

| 2,2 ,5,5 TETRA CHLORO BENZIDINE |

| 1.8 NAPTHO SULTONE |

| 2 ACETAMIDO PHENOL |

| 2 AMINO 5 METHOXY BENZENE SULFONIC ACID ( MW 203) |

| 2 AMINO PHENOL 4 SULFONIC ACID |

| ACETYL 2 AMINO PHENOL 4 SULFONIC ACID |

| 2 AMINO PHENOL 4,2 CARBOXY SULPHANILIDE |

| 2 AMINO TEREPHTHALIC ACID DIMETHYL ESTER |

| 2 METHYL 5 NITRO PHENOL |

| 2 METHYL 5 NITRO PHENOL |

| 2 NITRO 4 AMINO DIPHENYLAMINE 4 SULFONIC ACID (2-NADAPSA) |

| 2 NITRO PARA PHENYLENE DIAMINE ( 2 NITRO P.P.D) |

| 2 PYRIDINE |

| 2,3 AMINO PHENYL SULFONIC NAPTHLENE 6,8 DI SULFONIC |

| 2,4 DIHYDROXY QUINOLONE ( D.H.Q.) |

| 2,4 DINITRO ANILINE |

| 2,5 DICHLORO 1,4 SULFO PHENYL 3 METHYL 5 PYARZOLONE |

| 2,5 DICHLORO PARA NITRO ANILINE |

| 2,5 DICHLORO PARA PHENYLENE DIAMINE |

| 2,5 DICHLORO SULFANILLIC ACID |

| 2,5 DIMETHOXY ANILINE |

| 2,6 DICHLORO PARA NITRO ANILINE |

| 2.5 DICHLORO ANILINE |

| 2.6 DIAMINO TOLUIDINE |

| 3 AMINO 4 METHOXY BENZENE SULFONIC ACID |

| 3 AMINO PROPRONYLANILIDE |

| 3,3 DICHLORO BENZIDINE DI HCL ( MW 257 ) |

| 3,4 DICHLORO ANILINE |

| 4 AMINO DIPHENYLAMINE 2 SULFONIC ACID |

| 4 B ACID |

| 4 CHLORO 2 AMINO PHENOL ( 4 CAP ) |

| 4 CHLORO 2 AMINO PHENOL 6 SULFONIC ACID ( 4 CAPSA ) |

| 4 HYDROXY N-METHYL 2 QUINOLONE ( 4 HMQ ) |

| 4 METHOXY ORTHO NITRO ANILINE |

| 4 NITRO 2 AMINO PHENOL |

| 4 NITRO 2 AMINO DIPHENYLAMINE 4 SULFONIC ACID (4-NADAPSA) |

| 4 NITRO 2 AMINO PHENOL 6 SULFONIC ACID ( 4 NAPSA ) |

| 4 NITRO ANTHRANILLIC ACID |

| 4 NITRO META PHENYLENE DIAMINE ( 4 NITRO M.P.D.) |

| 4 NITRO ORTHO ACETYL ANISIDINE |

| 4 NITRO ORTHO ACETYL ANISIDINE |

| 4 SULFO 1,8 NAPTHALIC ANHYDRIDE |

| 4 SULFO ANTHRANILLIC ACID ( PURIFIED ) |

| 4 SULFO ANTHRANILLIC ACID ( STANDARD ) |

| 4 SULFO NAPTHALIC ANHYDRIDE |

| 4,4 DIAMINO SULFANILIDE (DASA ) |

| 4,4 DIAMINO BENZANILIDE (DABA) |

| 4,4 DIAMINO STILBENE 2,2 DISULFONIC ACID ( DASDA ) |

| 4.4 DINITRO STILBENE 2,2 DISULFONIC ACID ( DNSDA) PURIFIED |

| 4.4 DINITRO STILBENE 2,2 DISULFONIC ACID ( DNSDA) STANDARD |

| 5 AMINO 2 METHOXY BENZENE SULFONIC ACID |

| 5 NITRO ANTHRANILLIC ACID |

| 5 SULFO ANTHRANILLIC ACID |

| 6 ACETYL AMINO 2 AMINO PHENOL 4 SULFONIC ACID |

| 6 BROMO 2,4 DINITRO ANILINE |

| 6 CHLORO 2 AMINO PHENOL 4 SULFONIC ACID |

| 6 CHLORO METANILLIC ACID |

| 6 NITRO 1 DIAZO 2 NAPHTHOL 4 SULFONIC ACID |

| 6 NITRO 2 AMINO PHENOL 4 SULFONIC ACID ( 6 NAPSA ) |

| ACETYL BROENNERS ACID |

| ACETYL GAMMA ACID |

| ACETYL H ACID |

| ACETYL J ACID |

| ACETYL M-PHENYLENE DIAMINE 4 SULFONIC ACID |

| ALPHA NAPTHYLAMINE |

| AMINO G ACID |

| AMSTRONG ACID |

| ANILINE 2,4 DISULFONIC ACID |

| ANILINE 2,5 DISULFONIC ACID |

| ANTHRANILLIC ACID |

| BENZATHRONE |

| BENZIDINE 2,2 DISULFONIC ACID ( BDSA ) |

| BENZOYL J ACID |

| BON ACID |

| BROENNERS ACID |

| C ACID |

| CHLORANIL |

| COPPER ACETATE |

| COPPER SULPHATE ( AGRICULTURAL GRADE ) |

| COPPER SULPHATE ( ELECTROPLATING GRADE ) |

| COPPER SULPHATE (ANIMAL GRADE ) |

| D ACID ( NAPTHYLAMINE 5 SULFONIC ACID ) |

| DI ETHYL META AMINO PHENOL ( DEMAP ) |

| DIETHYL PHTHALATE |

| DINITRO STILBENE 2,2 DISULFONIC ACID ( DNSDA)-PURIFIED |

| DINITRO STILBENE 2,2 DISULFONIC ACID (DNSDA)- NORMAL |

| EPSILONE ACID |

| ETHYL BENZYL ANILINE SULFONIC ACID |

| F.C.ACID |

| SULFO FC ACID |

| G SALT |

| GAMMA ACID |

| H ACID ( MW 319 ) 100% BASIS |

| H ACID (MW 341 ) 100% BASIS |

| HYDRAZO BENZENE |

| J ACID |

| K ACID ( 2 NAPHTHYLAMINE 3.6.8. TRISULFONIC ACID ) |

| LEUCO QUINIZARINE |

| MESALAMINE ( 5 AMINO SALICYLIC ACID ) |

| META AMINO ACETANILIDE 4 SULFONIC ACID |

| META AMINO ACETANILIDE HCL ( FREE BASE ) |

| META AMINO METHOXY AZO SULFONIC ACID (MW 307 ) |

| META AMINO PHENOL |

| META CHLORO ANILINE |

| META NITRO ANILINE |

| META PHENYLENE DIAMINE ( M.P.D. ) |

| META UREIDO ANILINE |

| METANILLIC ACID |

| METHYL ANTHRANILATE |

| M-NITRO CHLORO BENZENE ORTHO SULFONIC ACID (MNCBOSA) |

| MONO CHLORO ACETIC ACID |

| M-PHENYLENE DIAMINE 4 SULFONIC ACID ( FREE ACID) 99% |

| M-PHENYLENE DIAMINE 4 SULFONIC ACID ( SODIUM SALT ) |

| ACETYL M-PHENYLENE DIAMINE 4 SULFONIC ACID |

| M-PHENYLENE DIAMINE 4,6 DISULFONIC ACID ( MPDDSA) |

| N -ACETYL N-METHYL PARA PHENYLENE DIAMINE |

| N,N DIMETHYL PARA NITRO ANILINE |

| N.W ACID ( NEVILLE WHINTHERS ACID ) |

| N-ACETYL J ACID |

| O-AMINO PHENOL 4 SULFONIC ACID |

| O-DIANISDINE BASE ( BLUE B BASE ) |

| O-NITRO ANILINE P-SULFONIC ACID ( ONAPSA ) |

| O-NITRO CHLORO BENZENE SULFONIC ACID (ONCBSA) |

| ORTHANILLIC ACID |

| ORTHO ANISIDINE 4 SULFONIC ACID |

| ORTHO CHLORO ANILINE |

| ORTHO CHLORO PARA NITRO ANILINE |

| ORTHO NITRO ANILINE |

| ORTHO NITRO ANILINE PARA SULFONIC ACID |

| ORTHO NITRO TOLUIDINE 2 SULFONIC ACID |

| OXY KOCH |

| P.AMINO AZO BENZENE |

| PARA AMINO 3 METHOXY AZO BENZENE 3 SULFONIC ACID |

| PARA AMINO ACETANILIDE (MW 150 ) |

| PARA AMINO ACETANILINE 3 SULFONIC ACID |

| PARA AMINO AZO BENZENE 3,4 DISULFONIC ACID |

| PARA AMINO AZO BENZENE 4 SULFONIC ACID ( Y ACID ) |

| PARA AMINO BENZOIC ACID |

| PARA AMINO DIPHENYLAMINE 2 SULFONIC ACID |

| PARA ANISIDINE 2 SULFONIC ACID (PA2SA) |

| PARA CHLORO ANILINE HCL |

| PARA CHLORO ANILINE ( PHARMA GRADE ) |

| PARA CHLORO ORTHO NITRO ANILINE |

| PARA NITRO ANILINE |

| PARA NITRO ANILINE O-SULFONIC ACID |

| PARA NITRO CHLORO BENZENE O-SULFONIC ACID (PNCBOSA) |

| PARA NITRO TOLUIDINE ORTHO SULFONIC ACID ( PNTOSA) |

| PARA PHENYLENE DIAMINE |

| PARA PHENYLENE DIAMINE DI SULFONIC ACID ( PPDDSA ) |

| PARA PHENYLENE DIAMINE O-SULFONIC ACID |

| PHENYL CARBOXY GAMMA ACID |

| PHENYL HYDRAZINE HCL |

| PHTHALIMIDE ( PURIFIED GRADE ) |

| PHTHALIMIDE ( TECHNICAL GRADE ) |

| QUINIZARINE |

| R SALT |

| RESIST SALT ( M-NITRO BENZENE SULFONIC ACID ) |

| RESORCINOL |

| SCHAEFFERS ACID |

| SODIUM BISULPHITE |

| SODIUM META NITRO BENZENE SULPHONATE (PURITY 96%) |

| SODIUM MONO CHLORO ACETATE |

| SODIUM NAPTHIONATE |

| SULFANILLIC ACID ( PURIFIED GRADE WHITE POWDER ) |

| SULFANILLIC ACID ( TECHNICAL GRADE GREY POWDER ) |

| SULFO TOBIAS ACID (D ACID ) |

| SULPHO GAMMA |

| VINYL SULFONE 2,5 DIMETHOXY ANILINE BASE |

| VINYL SULFONE ACETANILIDE BASE ( PARA BASE ) ( MW 281) |

| VINYL SULFONE ORTHO ANISIDINE BASE |

| VINYL SULFONE PARA CRESIDINE BASE |

| VINYL SULFONE PYRAZOLLONE BASE |

Unmatched Purity and Reliability

With a purity level of 99%, these dye intermediates are crafted to provide consistent results in industrial applications. Their low moisture content preserves their performance and stability, making them suitable for long-term storage and use in demanding chemical processes.

Versatile Applications in Dye Manufacturing

Designed for use in dye manufacturing, these intermediates are available as powders or granules. Their neutral pH and customizable solubility allow them to be adapted for synthesizing various dye types, supporting industrial exporters, manufacturers, and traders through flexible integration in production workflows.

Exceptional Resistance and Shelf-Life

Benefit from the advanced resistance properties of these dye intermediates, including high durability against light, chemicals, and physical abrasion. The compounds maintain their quality with a shelf life of up to 24 months and provide confidence in supply and storage for industrial users worldwide.

FAQs of Dye Intermediates:

Q: How are dye intermediates used in industrial dye manufacturing?

A: Dye intermediates serve as foundational compounds in the synthesis of a wide array of dyes. They undergo chemical transformations and reactions in dye manufacturing processes, providing the necessary building blocks for vibrant and stable colorants.Q: What benefits do 99% purity dye intermediates offer to manufacturers?

A: The high purity ensures fewer impurities, resulting in enhanced consistency, improved dye quality, and reliable performance in industrial applications. It also supports efficient processing and minimizes waste during production.Q: Where can these dye intermediates be sourced?

A: These intermediates are exported, manufactured, supplied, and traded in India by reputable companies experienced in catering to the industrial dye sector.Q: When is the optimal time to use dye intermediates during the dye production process?

A: Dye intermediates are typically used at the early stages of dye synthesis, where they react with other chemicals to form the desired dye molecules. Timely integration ensures quality color development and stable formulations.Q: What is the process for handling and storing dye intermediates?

A: Due to their solid form, these intermediates should be stored in dry, tightly sealed containers away from direct sunlight and humidity. Proper storage helps maintain their purity and effectiveness throughout their 24-month shelf life.Q: How do the resistance properties of these intermediates benefit dye products?

A: Good light and chemical resistance provide longevity and durability to the colorants produced, ensuring dyes maintain their vibrancy and strength under harsh conditions and frequent usage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese